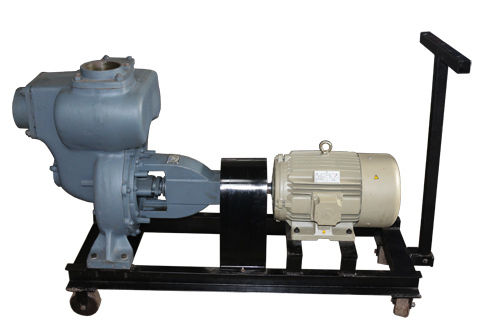

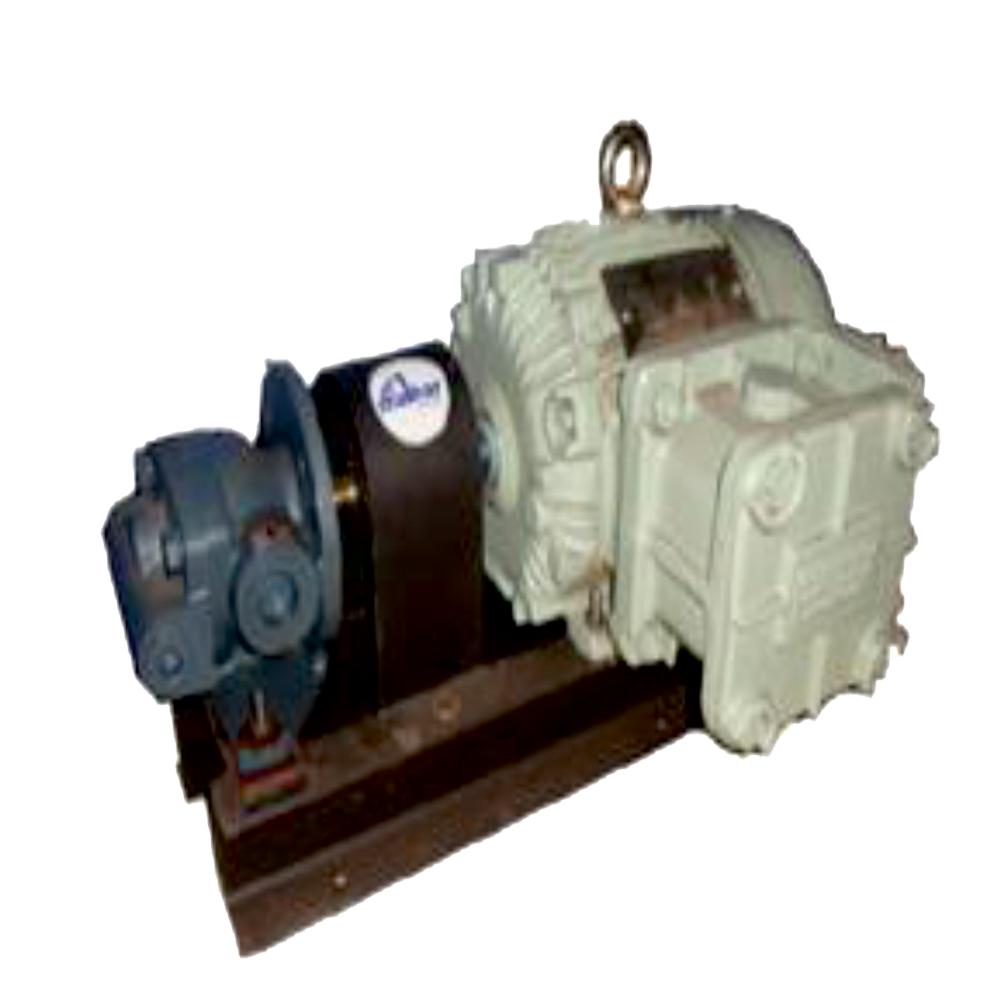

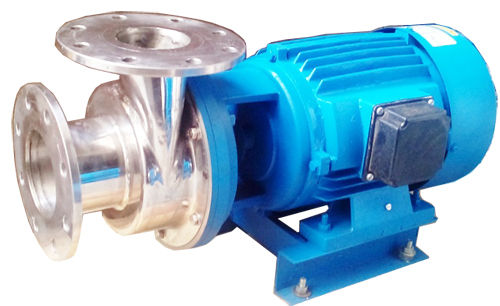

Self priming cum centrifugal Mud Monoblock pump

Product Details:

- Theory Centrifugal Pump

- Material Stainless steel

- Power Electric

- Pressure High Pressure

- Application Cryogenic, Fire, Maritime, Metering, Submersible, Sewage

- Click to view more

X

Self priming cum centrifugal Mud Monoblock pump Price And Quantity

- 1 Unit

Self priming cum centrifugal Mud Monoblock pump Product Specifications

- High Pressure

- Electric

- Centrifugal Pump

- Stainless steel

- Cryogenic, Fire, Maritime, Metering, Submersible, Sewage

Self priming cum centrifugal Mud Monoblock pump Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- 10 Unit Per Day

- 7-30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

"MP SERIES : -SELF PRIMING CUM CENTRIFUGAL MUD PUMPS : -APPLICATION : -Public utilities : For pumping muddy water, sewage, polluted liquids, solid and in swimming pool. Dewatering Basements, Trenches, Construction sites. Onboard shift, as bilge, for desk wash & engine cooling Tiles & Marble factories, effluent plants.Mobile Machinery : Cooling water for marine engines and shovels. Any application where priming is to be avoided.Industry : Transfer of clean or dirty neutral, acid or alkali liquidscontaining sand, mud or solids in suspension; clean or dirty lowviscosity petroleum product or solvents; milk of lime, caustic soda;washing, cooling, circulation; smoke scrubbing; emergency duty.Civil engineering : Flood drainage; sewage pumping; fire fighting; recovery of dangerous liquids.Naval duty : Loading and unloading; bilge pumping; washing, fire fighting, stripping,sanitary duty and circulation.Waste treatment: pumping polluted, hot or corrosive waste water containing sand, mud or solids insuspension; dosing neutralizing liquids; pumping out settled sludge.Construction industry : Dewatering excavation, canals or ponds; ground water dewatering with w ell pointsystem or drains; water supply from wells or canals; hosing down concrete castings.FAQs of Self priming cum centrifugal Mud Monoblock pump:

Q: What are the applications of the Self Priming Cum Centrifugal Mud Monoblock Pump?

A: The pump is suitable for Submersible, Fire, Cryogenic, Maritime, Metering, and Sewage applications.Q: What type of power source is required for this pump?

A: The pump operates on an electric power source.Q: What is the operating theory of this pump?

A: The pump functions based on the centrifugal pump theory.Q: Does the pump support high-pressure operations?

A: Yes, the pump is designed to handle high-pressure applications effectively.Q: What material is used for the construction of the pump?

A: The pump is constructed using stainless steel for durability and corrosion resistance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free