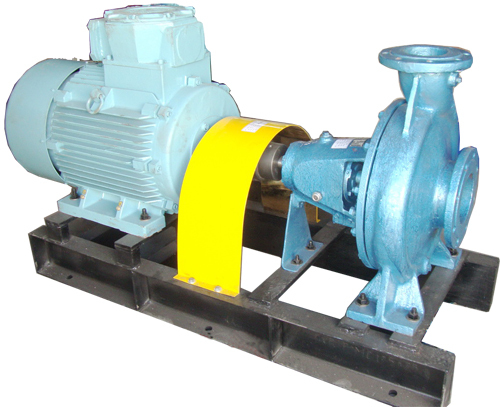

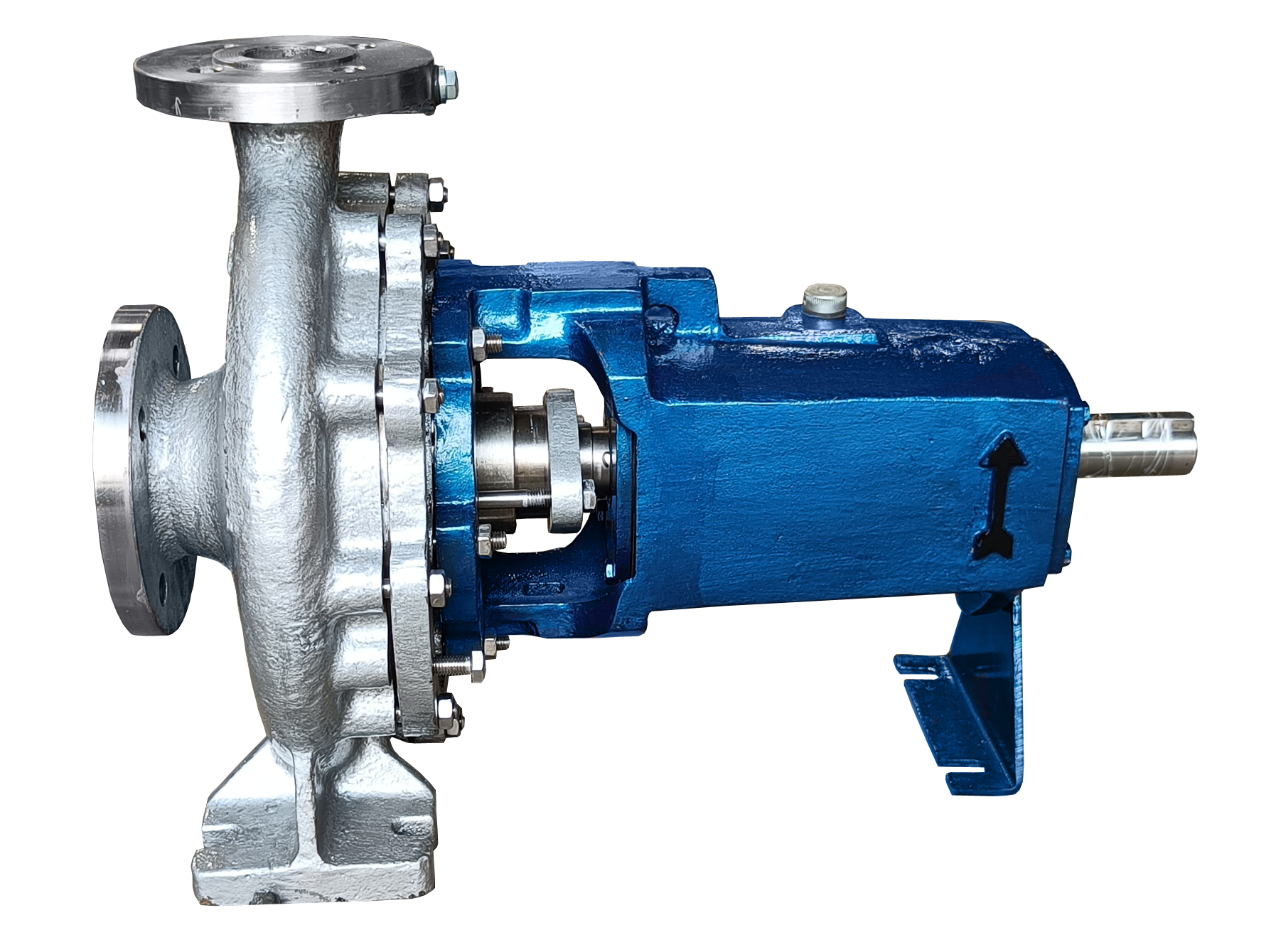

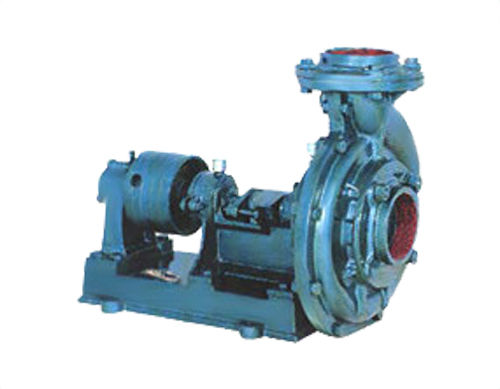

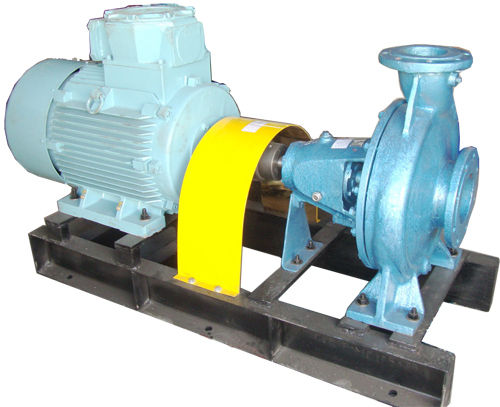

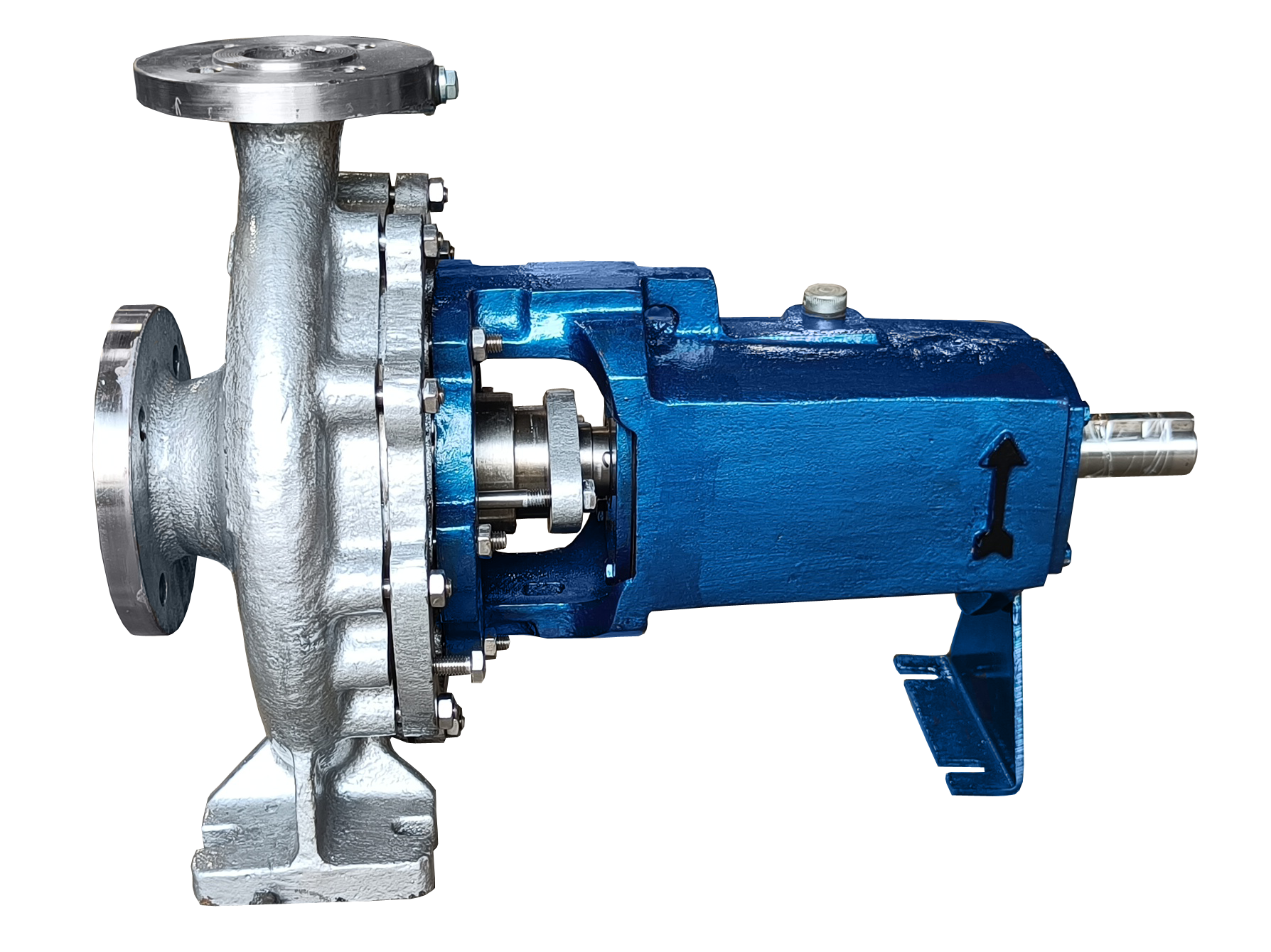

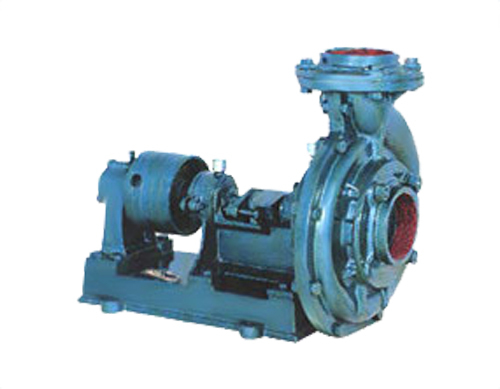

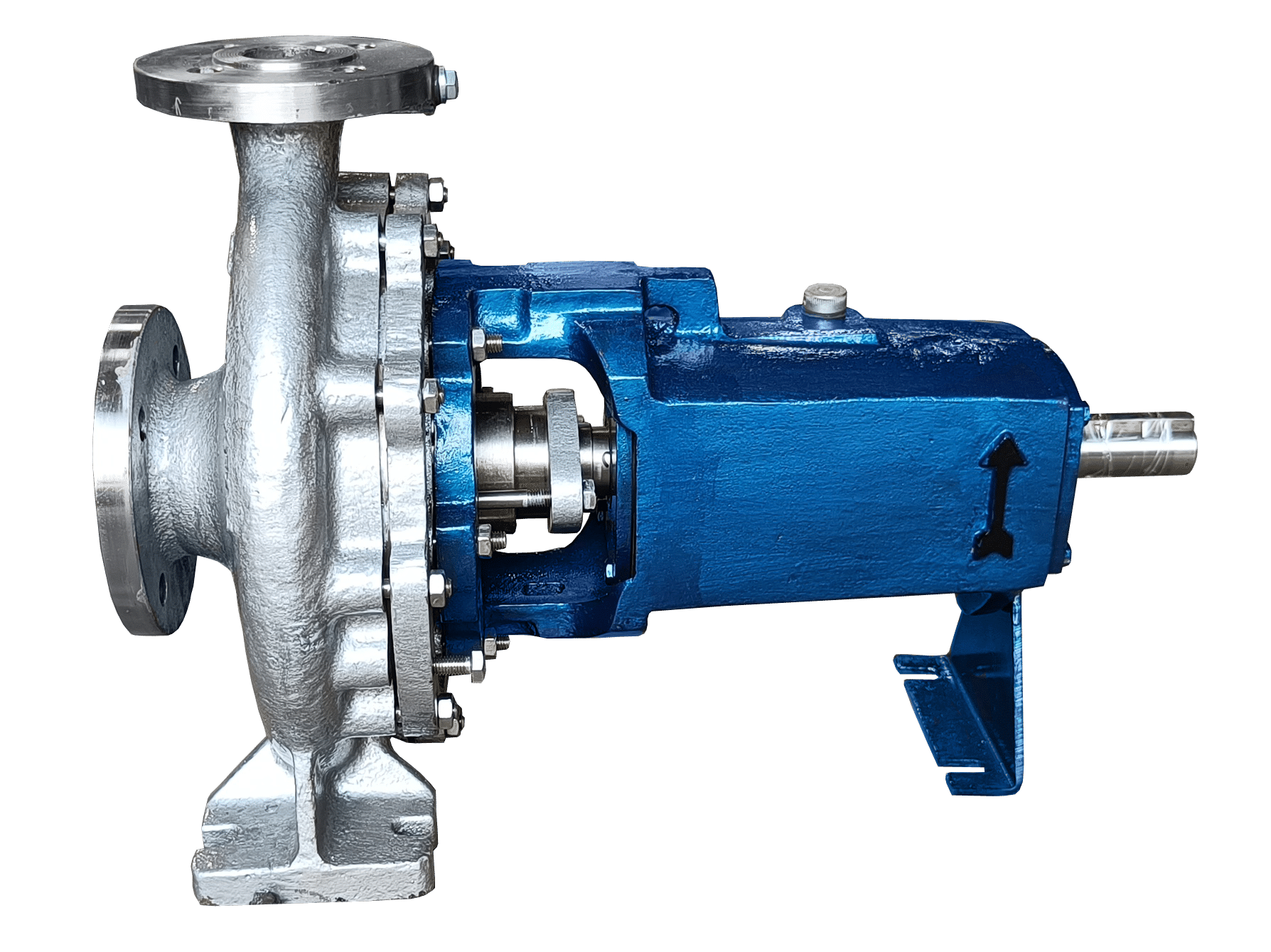

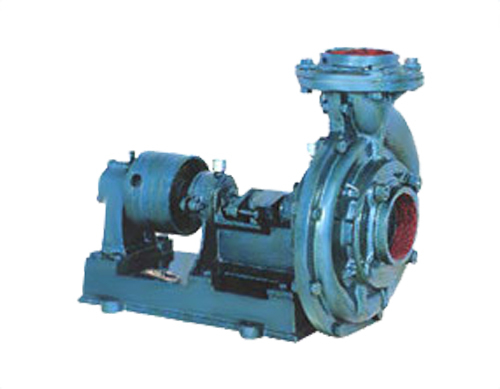

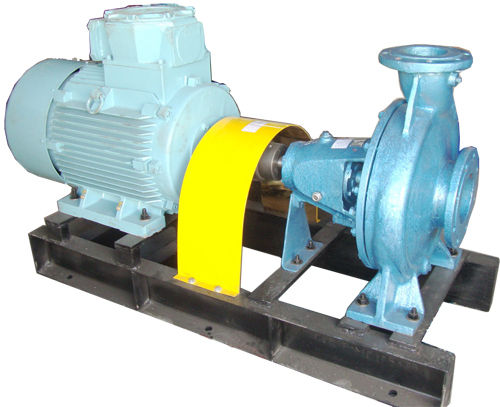

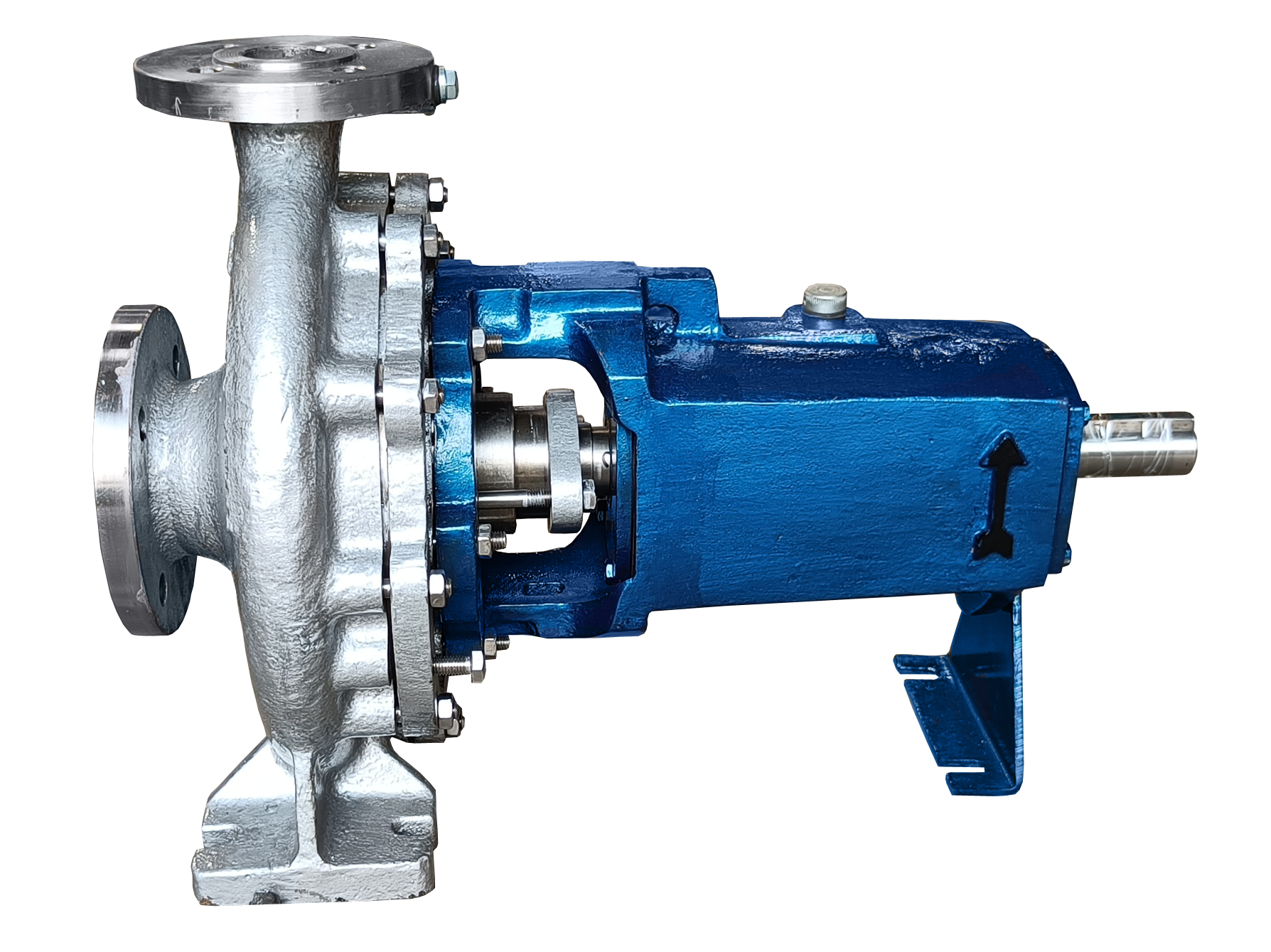

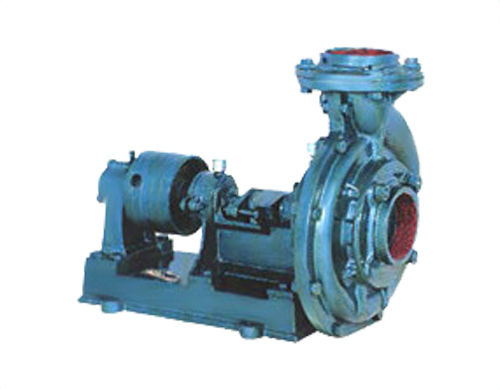

Different Types Of Back Pull Out Pumps And Chemical Process Pumps

Product Details:

- Control System Manual

- Caliber Standardized as per design

- Flow Rate Varies based on model and configuration

- Speed Standard speeds typically 1450 RPM or 2900 RPM

- Inlet/Outlet Flanged connections

- Voltage Standard voltage ranges 220V/440V

- Features Back pull-out design for easy maintenance; suitable for chemical processes

- Click to view more

X

Different Types Of Back Pull Out Pumps And Chemical Process Pumps Product Specifications

- Horizontal mounted

- Capable of handling medium to high temperatures

- Chemical processing industrial liquid transfer

- Mechanical seals

- Customized based on requirements

- Back pull-out design for easy maintenance; suitable for chemical processes

- International standards for chemical pumps

- End suction

- Centrifugal pump theory

- Electric motor-powered

- Medium to high-pressure range

- Varies per model typically up to several meters

- 50 Hz or 60 Hz

- Back Pull-Out Pumps Chemical Process Pumps

- Self-priming or manual based on variant

- Standard speeds typically 1450 RPM or 2900 RPM

- Varies based on model and configuration

- Robust single-stage construction

- Standardized as per design

- Manual

- Chemical and industrial applications

- Stainless steel or other corrosion-resistant materials

- Designed for different pressure ranges

- Standard voltage ranges 220V/440V

- Flanged connections

- N/A (Electric powered)

Product Description

"BPO SERIES : -BACK PULLOUT PUMPS (WATER & CHEMICAL PUMPS)APPLICATION : -For pumping Clear / Turbid water / Chemicals & Volatile Liquids. Air conditional plants , power station , Mine Drainage ,Sprinkle systems fire fighting , Booster service , Oils Brine.OPERATING RANGE : - Delivery size up to 250 mm Capacity up to 990M3/hr Head up to 120 meters RPM 500 to 3600FAQs of Different Types Of Back Pull Out Pumps And Chemical Process Pumps:

Q: What type of applications are Different Types Of Back Pull Out Pumps And Chemical Process Pumps suitable for?

A: These pumps are designed for chemical and industrial applications, primarily for chemical processing and industrial liquid transfer tasks.Q: What material is used in the construction of Different Types Of Back Pull Out Pumps And Chemical Process Pumps?

A: These pumps are made from stainless steel or other corrosion-resistant materials to ensure durability and reliability in handling aggressive chemicals.Q: What is the theory behind the operation of Different Types Of Back Pull Out Pumps And Chemical Process Pumps?

A: These pumps operate based on centrifugal pump theory, ensuring efficient liquid transfer and consistent performance.Q: What is the working temperature range these pumps can handle?

A: Different Types Of Back Pull Out Pumps And Chemical Process Pumps are capable of handling medium to high temperatures, making them suitable for demanding chemical processes.Q: What are the connection and mounting details for these pumps?

A: They feature flanged inlet/outlet connections and are horizontally mounted for stability and ease of installation.Q: Are these pumps self-priming?

A: Certain variants are self-priming, while others require manual priming, depending on the selected model.Q: What maintenance features do the Different Types Of Back Pull Out Pumps have?

A: They are designed with a back pull-out construction, allowing for easy maintenance and reduced downtime during servicing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free